Should You Buy Steel or Carbide Cutting Tools?

When it comes to operating milling machines, you are typically putting a lot of force on your cutting tools. End mills are drill bits operating at high speeds and feeds will have to deal with intense fatigue, especially when machining harder materials like steel and cast iron. When it comes to purchasing milling cutters, the two most common options will be steel and carbide cutting tools. Understanding the differences between these two options is important if getting the most out of your tools matters to you.

Steel Tools

Steel is a name for an alloy of iron, carbon, and small amounts of other metals depending on the desired characteristics of the alloy. Steel is a great tool making material because it is strong, holds an edge well, and it is cost effective. Steel tools tend to be a very affordable option for machinists because it will be able to effectively cut a wide range of materials and will hold its cutting edges well.

Despite the fact that steel tools are readily available and reasonably priced, they do have their drawbacks. While steel is extremely hard, that hardness comes from heat tempering. After metal has been heated and quenched, it is at its hardest possible state. Tempering is a process that involves heating metal to a point and allowing it to cool in air to soften it to the proper working hardness. This process helps to rearrange the metal’s internal structure by rearranging the crystalline microstructures within the metal.

If steel tools reach a temperature that is too high, they can lose their temping and the cutting edges will begin to soften, lowering the tool life. Even high speed steel alloys which are designed to handle high heat can still lose their temper when exposed to high temperatures.

Carbide Tools

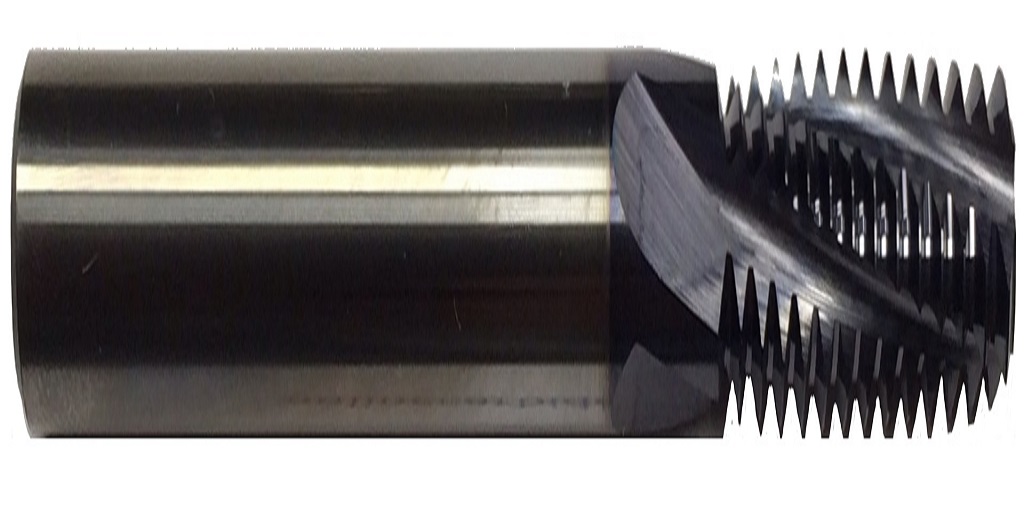

Carbide cutting tools are made up of a combination of tungsten carbide and cobalt metal. In its natural state, carbide is a grey ceramic powder. Even though it is only a powder, each granule is twice as rigid and dense as steel. This strength gives it some incredible cutting power, but it cannot be made into tools without some help. The cobalt binding material holds the powdered carbide in place like cement binding aggregate in concrete. While the binding metal provides the strength, the carbide serves to strengthen the cutting edges.

In addition to being stronger and more rigid than steel, carbide is also much more tolerant of heat. Ceramics do not need to be tempered and their crystalline structure remains solid even at extreme temperatures. This means that you can run your carbide tools at faster speeds and on harder materials than you could even with high speed steel cutting tools.

In addition to handling high temperatures, the rigidity of carbide tools also makes them extremely accurate. This is particularly true in the case of drill bits, which have a tendency to vibrate and wobble at high speeds. Solid carbide bits will vibrate less at high rotational speeds, meaning they are far more likely to drill precise holes compared to steel tools. This means that you can use longer bits in your milling machine and typically will not even have to spot drill beforehand.

If you are interested in finding some high quality carbide cutting tools, Online Carbide is a great place to start. They are an American manufacturer of solid carbide end mills and drill bits that are precision ground from micrograin tool carbide. You can see their full catalogue of carbide milling tools when you visit www.onlinecarbide.com.

For more information about Best End Mills For Aluminum and Drill Mills Please visit : Online Carbide.